After a failed attempt to install some B8 seats into my B6, I elected to go period correct. You know, because period correct is cool… not because I totally failed to make a relatively straight forward install work and needed to hit the easy button. When a set of B7 Recaro seats in pretty great condition showed up on eBay I jumped on them. I’m super happy with how they’re turning out – so far.

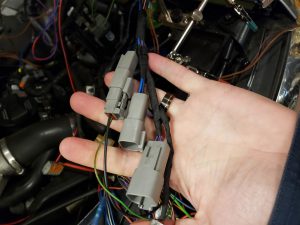

First things first, I tackled the front seats. Now, I know what you’re thinking: “Upgrading seats is a no-brainer.” But trust me, it’s not all sunshine and rainbows. I encountered my first hurdle when I discovered that the driver’s seat was giving me an airbag warning. I went through all the connections, all looked good. There’s a service bulletin on the seats because of a connector can fail… not that, already fixed. After tearing my hair out (what little I have), I took another look at the connectors. Driver’s side plug didn’t look like it was seating all the way. Turns out there was a small piece of broken plastic sitting in the bottom, just big enough to make the connection sporadically blip. It took some digging to remove the culprit, but problem solved.

The good news is that both front seats are now up and running smoothly, and I’m loving the added warmth courtesy of the seat heaters – perfect for those chilly mornings or cozy evenings behind the wheel. The Recaro seats are a huge upgrade from the base seats, with much better lateral support, and the passenger seat is now motorized.

However, not all is rosy just yet. The rear seat backs are a bit more high-maintenance than I anticipated. Specifically, both passenger and driver sides feature latches that require a key – which, of course, I didn’t have. No worries, though; the keyed portion of the latch is all in the plastic handle, a simple swap in from my stock seats fixed that.

Additionally, I found the latch on the rear driver’s side would not latch. I found that if I manipulated it by hand, it would fully latch, but just didn’t spring into place. I was hoping it was just in need of lubrication, but unfortunately it is broken.

The original seats from the car, however, provided a working spare. I transferred the latch mechanism from the old seat to the new one, which was actually quite straightforward once I understood the process. YouTube, once again, kept me from failing.

The passenger side rear seat back still needs some TLC, but it’ll have to wait for now – there’s a pesky wire in the way that’s making it tricky to remove.

All in all, I’m thrilled with the progress so far.